The edible oil plate filter is a kind of equipment used to filter edible oil. It is mainly used for solid-liquid separation and oil-water separation. The plate and frame oil filter can remove solid impurities and water from the oil. In the food processing industry, the edible oil plate filter can be used together with an oil press machine. It can also be used to filter water and impurities in transformer oil, turbine oil, engine oil, diesel oil, aviation hydraulic oil, and so on.

filtered oil

plate and frame oil filter real shot

Edible oil plate filter advantages

- Simple structure, easy operation and low operation cost. The filter pad and filter plate are fixed in multiple directions, so the filter cloth keeps flat and smooth, easy to use.

- Clean and hygienic. The material contacting oil is made of 304 stainless steel and meet the food safety standards. The filter plate is made of reinforced polypropylene by one-time molding, which is acid proof, anti-alkali, and corrosion-resistant.

- High filtration efficiency, time-saving and labor-saving

Structure details of oil filtering machine

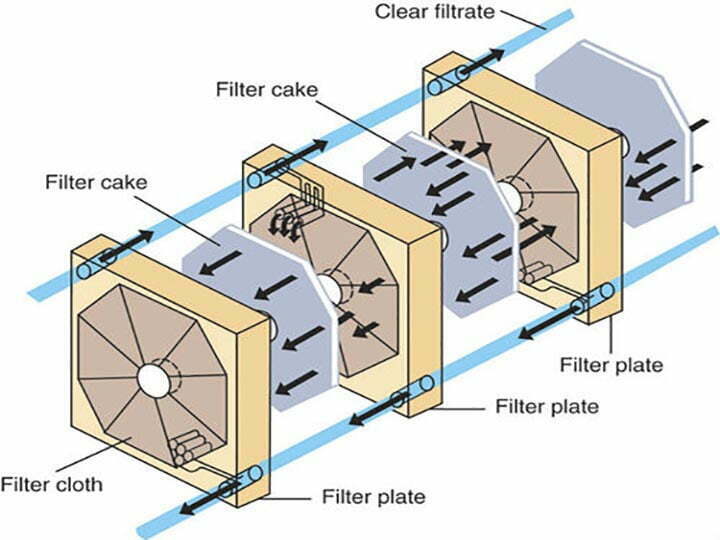

The edible oil plate filter mainly contains the oil pipe, filtering plate, frame, oil pan, etc. A filter paper/cloth as a filter medium is placed between the filter plate and the filter frame. The filter plate and the filter frame are fixed by the pressure of the pressing device to form a separate filter chamber. The filter paper or filter cloth pressed between the filter plate and the filter frame plays a filtering role.

oil filtering machine details

pressure gauge

Working principle and process

As for the working principle and process of the edible oil plate filter, Firstly, a certain number of filter plates are closely arranged in a row under the action of strong mechanical force, and a filter chamber appears between the filter plate surface and the filter plate surface. The material is sent to the filter chamber under strong positive pressure. The solid part of the filtered material entering the filter chamber is intercepted by the filter medium (such as filter cloth) to form a filter cake, and the liquid part is discharged from the filter chamber through the filter medium, so as to achieve the purpose of solid-liquid separation.

The edible oil plate filter is also equipped with a filter press with a rubber extruded membrane, and the compressed medium (such as gas and water) enters the back of the extruded membrane to push the extruded membrane to further dehydrate the extruded filter cake. After dehydration, release the mechanical pressing force of the filter plate, and gradually pull the filter plate apart.

plate and frame oil filter structure

Edible oil plate filter real shot

Main parameter

| Model | Number of filter plates | Filtration area | Power | Filter plate size | Dimension |

| TZB-20 | 20pcs | 3m2 | 1.5kw | 400x400mm | 1550x600x1400mm |

| TZB-30 | 30pcs | 4m2 | 1.5kw | 400x400mm | 1750x660x1400mm |

| TZB-44 | 44pcs | 6m2 | 1.5kw | 400x400mm | 2100x660x1400mm |

| TZB-62 | 62pcs | 8.5m2 | 2.2kw | 400x400mm | 2500x660x1400mm |

| TZB-70 | 70pcs | 9.5m2 | 2.2kw | 400x400mm | 2700x660x1400mm |