As the core equipment of oil processing, the stable operation of the oil extraction press is directly related to the production efficiency and oil yield. Whether it is screw oil press or hydraulic oil press, it needs regular maintenance and failure prevention. This article will be on the routine maintenance, common problems, and ways to deal with the three aspects of the details.

Screw oil press daily maintenance points

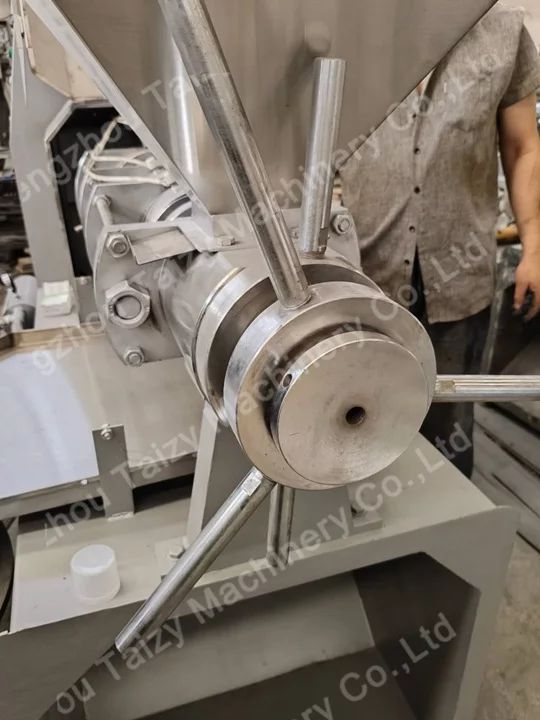

Regular cleaning of the press chamber and screw

After each production, it is recommended to remove the residue thoroughly to avoid oil accumulation, causing blockage or corrosion of the press chamber.

Lubrication check

Check the gearbox lubricant every 100 hours of operation, and keep the oil level moderate to prevent gear wear.

Electric control system check

Regularly check the heating temperature control device and motor line to ensure stable temperature and sensitive control.

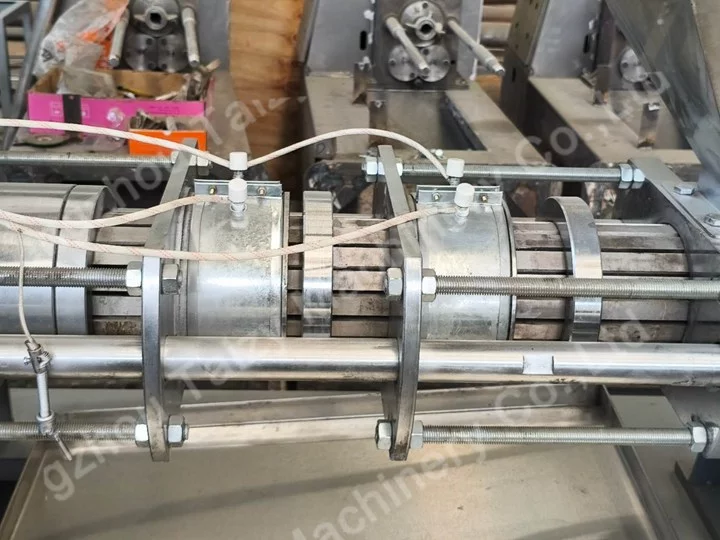

Belt and screw wear detection

If the belt is found to be loose and the screw rattles, it should be replaced or adjusted in time to avoid damaging other parts.

Hydraulic oil press daily maintenance points

Hydraulic oil replacement and filtration

It is recommended to replace the hydraulic oil every 3 months to keep the system pressure stable; meanwhile, clean the oil circuit and oil tank.

Hydraulic cylinder seal ring check

If oil seepage is found in the cylinder, the seal ring should be replaced in time to prevent insufficient pressure affecting the oil discharge.

Pressure gauge and electric control safety check

Check whether the power line and grounding are firm, and whether the pressure gauge reading is accurate to prevent overpressure operation.

Pressure plate and mould cleaning

The mould should be cleaned after each use to prevent blockage of fragrance oil residue and prolong the service life of the equipment.

Comparison table of common faults and troubleshooting methods

| fault phenomenon | Applicable models | Possible causes | Solutions |

| Decreased oil yield | Screw and hydraulic universal | Improper moisture content of raw materials, clogging of the press chamber | Adjust the humidity of raw materials and clean the press chamber |

| Difficulty in starting the equipment | screw | Motor failure, loose wiring | Check motor and power connections |

| Rattling or violent vibration of the chamber | screw | Worn screws, loose bearings | Replace screw or tighten bearing |

| Insufficient hydraulic pressure | hydraulic | Insufficient hydraulic fluid, cylinder pressure relief | Replenish hydraulic fluid, check seals |

| High oil residue | Screw and hydraulic universal | Clogged oil filtration system, low press temperature | Clean filters and adjust heating temperature |

Maintenance Tips

- Idle cleaning at the end of each day’s operation to reduce residue accumulation

- The equipment should be coated with anti-rust oil and stored in a dry environment after a long period of downtime.

- It is recommended that a complete overhaul be carried out every 6 months or that the factory maintenance service be contacted

Conclusion

As high-intensity operation equipment, reasonable routine maintenance can not only prolong the service life of the equipment but also effectively reduce the failure rate and improve the production capacity. Whether it is screw oil press or hydraulic oil press, a set of standardised maintenance mechanism should be established.

When you buy the Taizy oil extraction press, we provide remote technical guidance, maintenance training, and spare parts support. Please feel free to contact us for a detailed service programme.