As people pay more attention to a healthy diet, the purity, nutrient content, and safety of the edible oil production process are getting more and more attention from consumers. At the same time, the food processing industry, small oil mills, and agricultural products processing base to the degree of automation, output and stability of the oil press equipment requirements are increasingly increased.

In this context, screw press oil extraction has gradually become one of the mainstream equipment in the oil processing industry by virtue of its high efficiency oil yield, easy operation, and wide adaptability to raw materials. Screw oil press is widely used in the production of peanut oil, rapeseed oil, coconut oil, and other vegetable oil pressing.

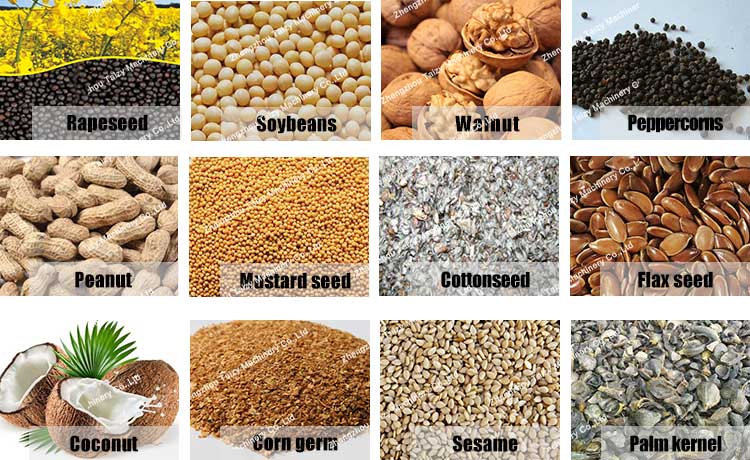

What are the common raw materials for oil extraction?

Screw oil presses can be applied to a wide range of raw materials with high oil content, including but not limited to peanuts, rapeseed, soybeans, sunflower seeds, sesame seeds, coconuts, walnuts, cottonseed, tea seeds, flaxseed, almonds, and grapeseed.

Most of these raw materials come from agricultural by-products or cash crops, and are ready to enter the oil extraction process after proper dehulling, cleaning, and drying treatment. Depending on the oil content, fibre structure, and fatty acid characteristics of different raw materials, users can also choose to operate in hot or cold pressing to better retain the nutritional value and flavour of the oil.

Working principle and production process of screw press oil extraction

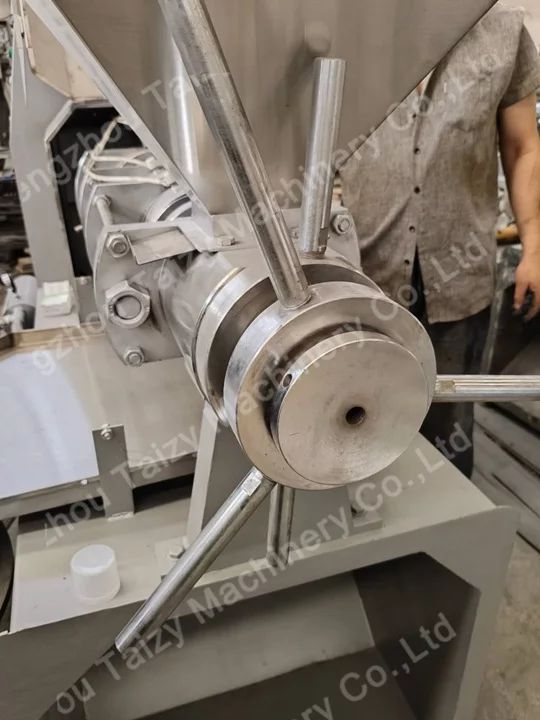

Screw oil press machine mainly works through the continuous rotation of the screw shaft. The raw material in the press chamber is gradually pushed and subjected to increasing pressure to achieve the physical extrusion and separation of oil and grease.

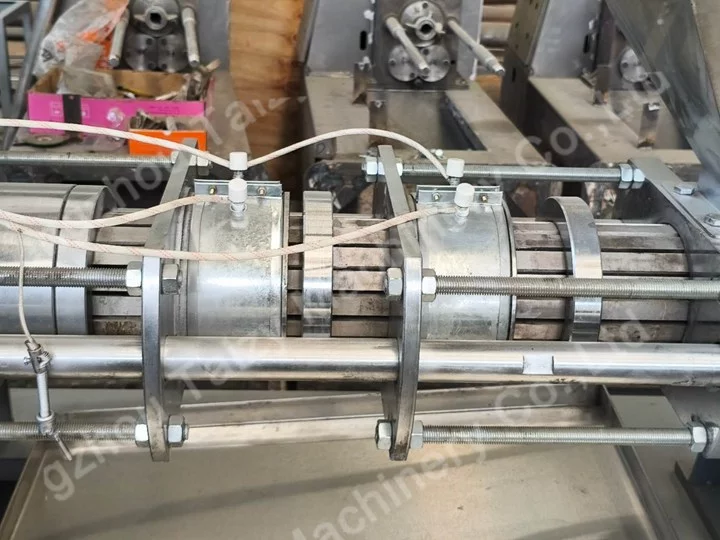

Before pressing, raw materials like peanuts, rapeseed, soybeans, and sesame need to be cleaned and dried. Some materials are also fried to improve oil yield. Once the machine is preheated by the heating ring, it’s ready to start working.

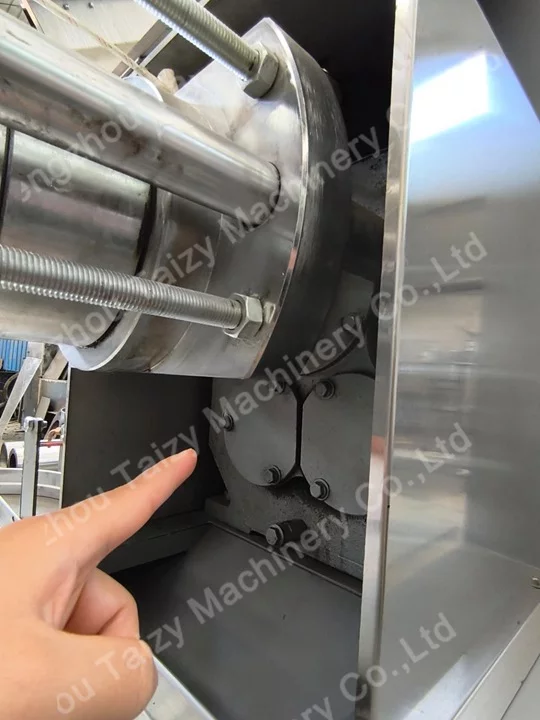

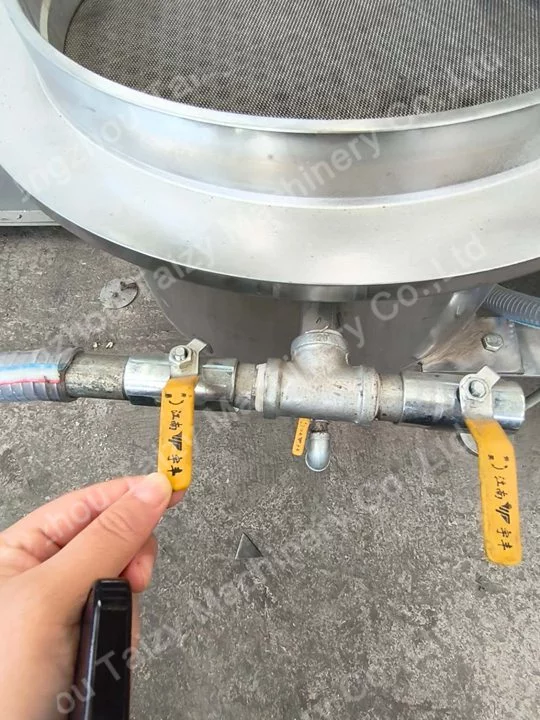

The raw material enters the press chamber and is gradually compressed by the rotating screw. As pressure and friction build up, oil is released from the seeds and flows out through small gaps in the press. The crude oil is collected and filtered in a vacuum oil drum to remove impurities, resulting in clean, edible oil.

The leftover oil cake is discharged automatically, with a thickness of just 1–3mm and a low residual oil rate of 6–7%. The machine uses a three-stage pressing system, supports both hot and cold pressing, and achieves high oil yield with efficient, one-time hot pressing.

Advantageous features of the Taizy screw oil press machine

Screw oil press machine has several significant advantages, with full consideration of production efficiency and operational stability in its design.

Firstly, it adopts a three-stage pressing structure, which can be used for both hot and cold pressing. In hot pressing, the oil can be extracted once, which greatly improves the oil yield, and the oil content of the residual cake is as low as 6%-7%. The equipment is equipped with a six-stage motor drive system, with strong power, low energy consumption, stable operation, and low noise even in long-time continuous operation.

The press bar gap can be adjusted to suit different materials, ensuring efficient oil extraction. The machine has a compact design, is easy to install and maintain, and has low operating costs with minimal need for part replacement. It also meets food safety standards, making it ideal for farmers, oil mills, and small to medium-sized processing plants.

Technical parameter

| Model | TZ-70 | TZ-80 | TZ-100 | TZ-120 | TZ-130 | TZ-165 |

| Screw diameter | 70mm | 80mm | 100mm | 120mm | 130mm | 160mm |

| Capacity(kg/h) | 50-80 | 80-140 | 150-200 | 250-300 | 350-400 | 700-800 |

| Motor | 3kw | 5.5kw | 7.5kw | 11kw | 18.5kw | 30kw |

| weight (kg) | 317 | 510 | 750 | 895 | 1210 | 1545 |

| Size(mm) | 1350*1050*1110 | 1650*1230*1450 | 2000*1330*1600 | 2040*1380*1600 | 2450*1380*1980 | 2620*1350*1900 |

Taizy screw press oil extraction for sale

As a kind of oil processing equipment with mature structure and advanced technology, the screw oil press not only improves the oil extraction efficiency and oil purity, but also significantly reduces the labour and operating costs. In the trend of rising consumption of vegetable oil and the popularity of natural health products, investing in a reliable screw press is undoubtedly a wise choice to enter the oil processing industry.

If you want to know the different output models, raw material suitability, or specific price information, please contact us at any time. We will provide you with professional equipment selection advice and technical support.