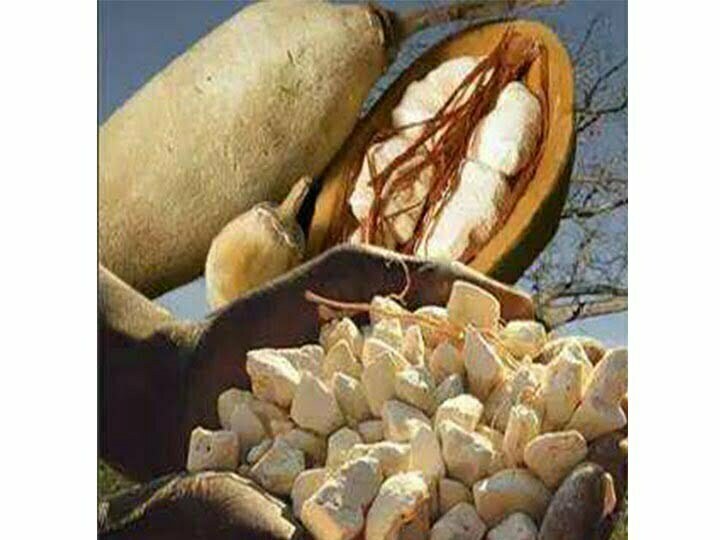

Baobab oil is extracted from the seeds inside the baobab fruit and is golden in color. Baobab oil can be obtained either hot-pressed or cold-pressed from a baobab seed oil press machine. The baobab oil pressing machine dissolves the oil molecules by increasing the temperature and extrudes the oil from the baobab seed with the help of external mechanical force. It does not need any chemical raw materials during the pressing process, and the oil produced has a strong fragrance. The baobab seed does not foam during cooking and is widely welcomed by our consumers around the world.

Introduction to baobab seed oil

Baobab oil contains 33% saturated fatty acids, 36% monounsaturated fatty acids, and 31% polyunsaturated fatty acids. Rich in vitamins A, E, F and sterols. It has a strong ability to resist rancidity and has a good shelf life, but it should also be kept in a cool and sealed manner.

The main uses of baobab oil are external skincare for emollients and anti-aging. It can be applied and massaged directly on the skin. It is easily absorbed by the skin quickly and does not leave any greasy feeling, suitable for all kinds of skin. It promotes the rejuvenation of skin cells, helps maintain skin health, improves skin elasticity, and delays skin aging. The baobab seed oil can also lighten scars and relieves skin irritations.

Besides, baobab oil has a smooth texture and nourishes hair, softening hair for silky smoothness.

Highlights of baobab seed oil press machine

- Automatic temperature control, fast oil extraction, good oil quality,

- The screw oil press adopts vacuum filtration for rapid oil purification.

- Continuous work, simple operation, one-key start, saving time and effort.

- A wide range of uses saves energy and is cost-effective. This baobab oil pressing machine mainly processes oil-bearing materials: sesame, walnut kernel, peanut kernel, tea seed, flax, cocoa butter, pine nut, almond, olive, and other high oil crops.

How is baobab oil extracted?

Pressing method: The pressing method has a long history, and its technological process is relatively simple. After roasting the baobab seeds, the material is squeezed out of the oil by mechanical means. The traditional pressing method requires operators to pay heavy manual labor. In the extruded oil residue (oil cake), the residual oil content is quite high, thus wasting extremely valuable oil resources. The modern pressing method is an industrialized and automated operation, and the problem of high residual oil content in the oil residue has been well solved.

Baobab oil extraction process

From the pretreatment of pressed raw materials, there are the cold pressing method and hot pressing method. For hot pressing, the oil crops are roasted and dried before the pressing of a screw oil press machine. The purpose is to reduce the moisture of the raw baobab seeds and increase the activity and fluidity of the oil molecules, thereby improving the oil yield, and ensuring the fragrance of the baobab oil.

Hot pressing method: raw baobab seeds – roasted baobab seeds – pressing to get crude baobab oil – filtering to get clean baobab oil

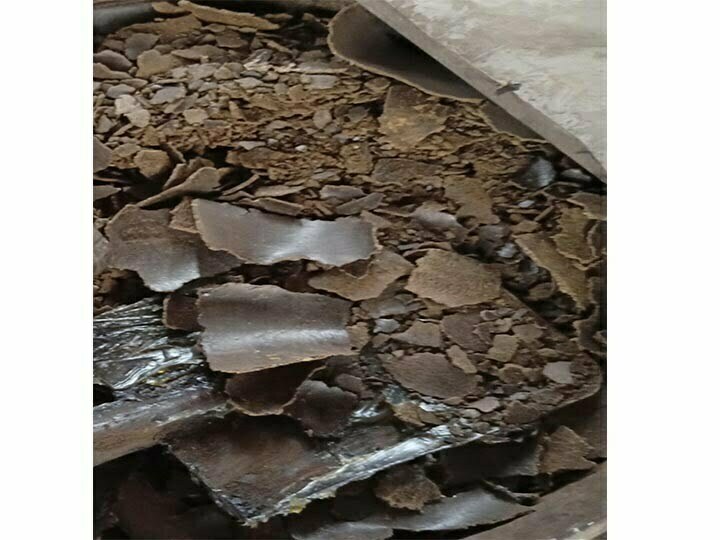

Specifically speaking: The baobab seeds first enter the press chamber of the baobab seed oil press machine. As the press chamber of the screw oil extractor rotates, the pressure increases and the baobab seeds are continuously squeezed. The particles of the baobab seeds that are in direct contact generate pressure with each other, which causes the deformation of the seed material to produce oil. Due to the dual effects of temperature and pressure during pressing, the protein will continue to deteriorate, which in turn affects the plasticity of the pressed material. The proper degree of protein denaturation can ensure good baobab oil. After being squeezed out of the chamber, the baobab seeds form baobab oil cakes.

Technical data of baobab oil pressing machine

| Model | TZ-70A | TZ-80A | TZ-100A | TZ-125A | TZ-150A |

| Screw diameter(mm) | 70 | 80 | 100 | 125 | 150 |

| Capacity(kg/h) | 50-80 | 125-150 | 200-250 | 250-350 | 500-600 |

| Motor(kw) | 5.5 | 5.5 | 7.5 | 15 | 22 |

| weight (kg) | 350 | 700 | 1100 | 1400 | 1700 |

There are 5 models of baobab oil pressing machines in the above table. The name of the model is based on the diameter of the screw. The output reaches from 30-1000kg/h, meeting the outputs of small, medium, and large oil processing organizations. The machine output can also be customized. The baobab seed oil press machine is made of food-grade stainless steel, meeting food safety standards.

Cold-pressed baobab oil extraction process

The basic process of cold pressing: raw baobab seeds — cold pressing (filtering is optional) — pure baobab oil

Cold pressing means that the raw materials are directly put into the oil press to squeeze out the oil without roasting. The baobab oil made by this method is relatively lighter in color and brighter in color, but the oil yield is relatively lower.

To make cold-pressed baobab oil, it is also commonly used a hydraulic oil press machine. The pressure of the cold-pressed baobab oil machine is high, and so is the work efficiency. The oil quality is pure. The baobab oil pressing machine adopts a fully automatic control system, the preheating temperature is automatically controlled, and the hydraulic system pressure is automatically controlled. The output of the cold oil press machine is generally 30-250kg/h.

How does a cold pressed baobab oil machine work?

In general, the baobab oil is pushed upwards by the force of the oil cylinder assembly inside the press assembly, the oil flows down from the oil gap of the baobab seed oil press machine, and flows into the oil storage barrel through the oil receiving pan. Here are the 4 steps for making cold-pressed baobab oil.

Startup: The motor starts and the hydraulic oil from the high and low-pressure double pump return to the oil tank through the high-pressure rotary valve 4.

Pre-pressure: The high-pressure rotary valve is turned to the right position, and the high-low pressure hydraulic oil of the double pump enters the upper chamber of the pressing cylinder through the high-pressure switching valve, and the cylinder starts to work for pre-pressing.

Pressing: When the pressure rises to 50Mpa, the low-pressure relief valve of the pump station is unloaded, and the high-pressure pump of the double pump supplies hydraulic oil for oil extraction. When the electric contact pressure gauge is adjusted to 45Mpa-55Mpa, the motor is powered off. When the pressure drops to 45Mpa, the motor starts. Through repeated squeezing, the baobab oil yield is high.

Pressure relief: After oil pressing, turn the high-pressure valve 4 to the left position, the hydraulic oil output from the double pump enters the lower chamber of the oil pressing cylinder through the hydraulic control check valve, and the pressure of the relief valve is set to 5Mpa. The valve is turned to neutral and the motor is de-energized.

If you are interested in this baobab seed oil press machine, please feel free to contact us. Our professionals will offer you specialized advice and favorable quotations.