The peanut oil press machine is also called a peanut oil extraction machine. It is a screw-type oil press. Commercial peanut oil-making machines can meet the needs of customers for cold pressing and hot pressing. We offer peanut oil presses with different production capacities, ranging from 30 kg/hour to 600 kg/hour.

The peanut oil press can not only be used alone, but it can also be used in a large-scale peanut oil press production line. Our company offers automatic oil extractors with different types and outputs to meet customers’ specific needs.

Video of groundnut oil press

Peanut oil production steps

- Raw material selection: Use peanuts with no mildew or other sundries to squeeze oil. When there are many impurities, they should be screened first.

- Roasting/drying: Use a roaster or dryer to remove the moisture in the peanuts. The moisture after baking should be kept at about 8.5%.

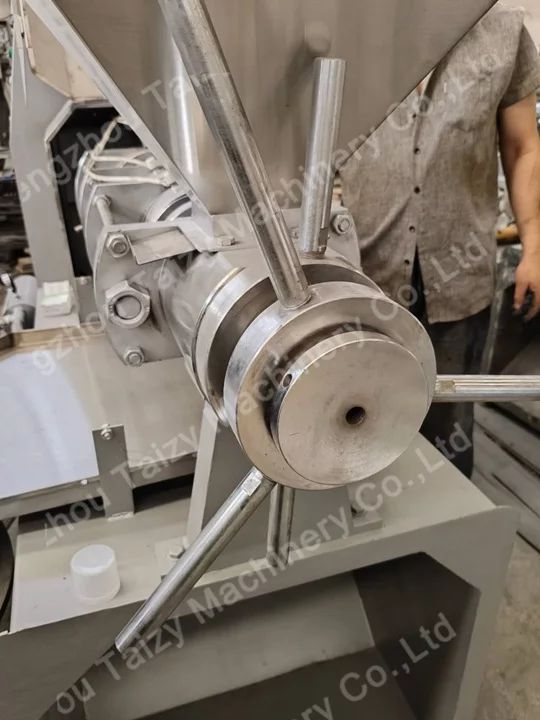

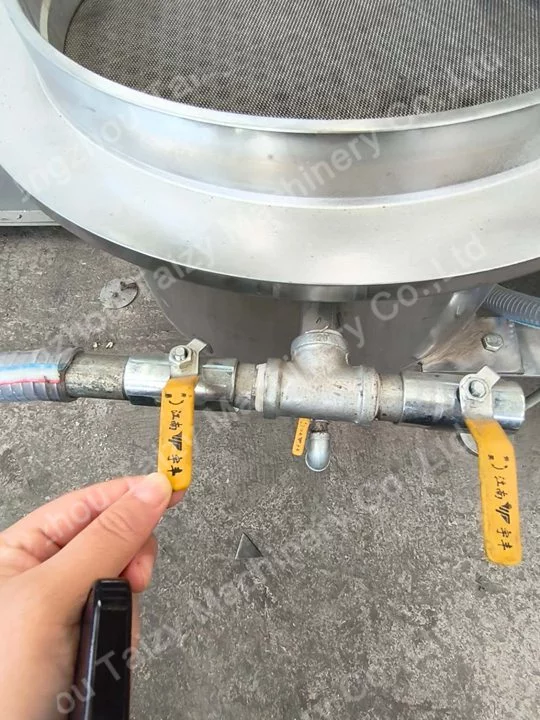

- Peanut oil pressing: Put the roasted peanuts at the entrance of the peanut oil press machine, and start the machine to automatically press the oil. At the same time, turn on the oil filter to clean the oil. After the peanuts are squeezed, peanuts form into oil cakes. You can observe the oil cake’s thickness to determine the degree of oil extraction.

- Filling: After filtering, use an oil filling machine to put peanut oil into special containers.

Automatic peanut oil press machine features

High oil yield

The peanut oil press machine is clean in a single press, with a high oil yield, and it saves labor and time. It can realize multi-stage propulsion in a single press, and the oil yield can increase by 10-30%. Compared with the old peanut extraction equipment, the normal oil yield can be 2 to 3 percentage points higher. It can process 50kg of peanuts on average, and the oil yield increases by 1~3kg of oil. The annual economic benefits are very considerable.

Safety and convenience

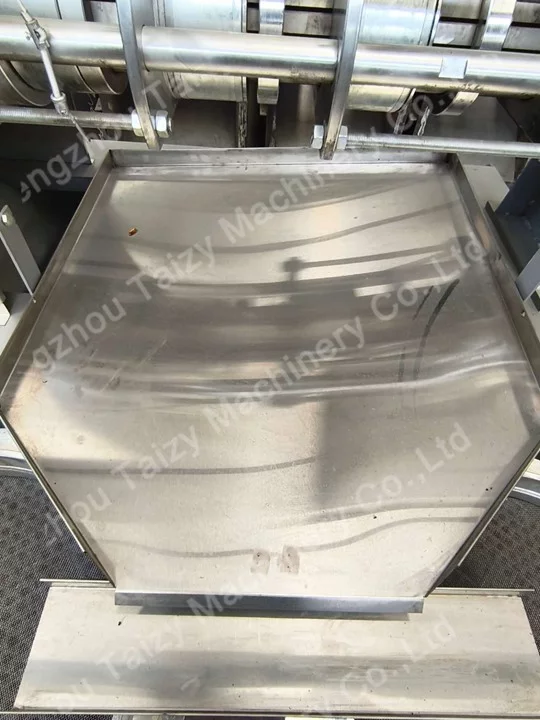

With exquisite structure, the peanut oil extraction machine occupies less space. The size of the oil workshop can be 10-20 square meters. With the adoption of full protection, the peanut oil extractor is safe and convenient. The complete set of the peanut oil-making machine is easy to operate and maintain.

Energy saving

The groundnut oil press reduces electric power by 40% with the same output. The peanut oil maker can improve the working efficiency by more than 30%.

Labor saving

The peanut oil extraction machine can realize automatic temperature control. The same output can save 60% of the labor force, one person can control the production.

Wide application

The industrial peanut oil press machine is a multi-purpose machine. It can squeeze peanuts, flax, sesame, rapeseed, okra, cottonseed, soybean, and 30 other kinds of oil crops.

Oil purity

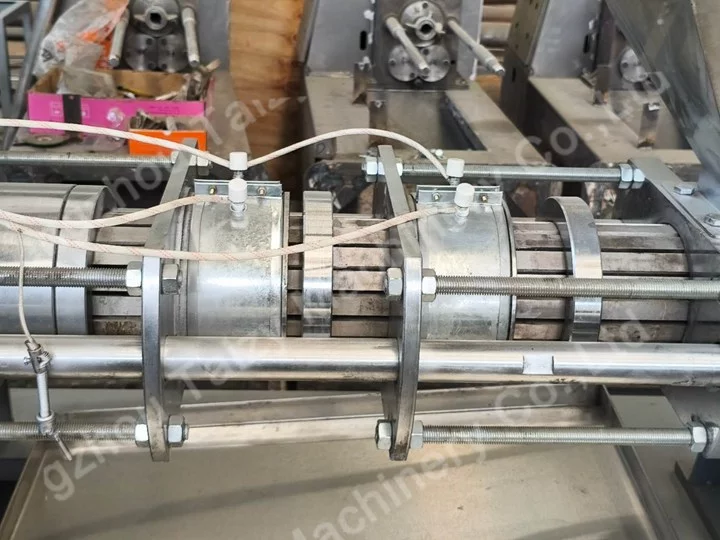

The screw oil press machine is hygienic, made of stainless steel. And vacuum filtration can improve oil purity, meeting the industrial standards.

Durable

The whole groundnut extraction machine body adopts wear-resistant steel and anti-fatigue castings, with stable performance and long-term continuous work. The machine table is made of a new material, electrostatic spraying, strong adhesion, oil resistance, and high-temperature resistance, which is clean and sanitary.

Typical technical data (TZ-80A)

| Type | TZ-80A |

| Screw diameter | 80mm |

| Power | 5.5kw |

| Voltage | 380V/50HZ/Three-phase |

| Capacity | 100kg/h |

| Size | 1650*1500*1600mm |

| Weight | 565kg |

We have peanut oil extractors with different outputs reaching from 30-600kg/h. For special needs, we also offer customized services.

The difference between hot and cold-pressed peanut oil

Hot-pressed groundnut oil

The hot pressing peanut oil process usually uses a roaster to roast peanuts before pressing. In addition, it will generate high temperatures when pressing the oil. The press destroys the structure of peanuts by high temperature to produce oil. The peanut oil produced by the hot pressing process has a high oil yield and a low residual oil rate.

As the high temperature destroys the structure of peanuts, the oxidation value of hot-pressed peanut oil increases. It is necessary to add synthetic antioxidants.

Cold-pressed peanut oil

Cold-pressed peanut oil uses a dryer to dry the selected peanuts at low temperatures and then squeezes them by purely physical methods. The temperature during the pressing process does not exceed 60°C. The peanut oil squeezed in this way can preserve the nutrient content of peanuts to a great extent. By the cold press, the peanut oil is lighter in color, higher in oil point, and has less oily smoke.

What is the peanut oil?

- Peanut oil is rich in soft phospholipids, stearic acid, and arachidic acid, and other nutrients that are helpful to people’s health.

- The zinc content of peanut oil is many times that of rapeseed oil and soybean oil. Long-term consumption of peanut oil can help supplement zinc.

- Groundnut oil contains a variety of anti-aging ingredients, which help delay aging.

- Peanut oil helps improve the memory of the human brain and delays the decline of brain function.

- Peanut oil has a protective effect on gastric mucosal damage and the effect of invigorates the spleen and stomach.

Typical export case

Peanut Oil Cold & Hot Pressing Machine Price In Nigeria

Contact us!

If you would like to learn more about oil press model selection and customization, please contact us, and we will provide you with a one-stop solution.