As an important piece of equipment in oilseed processing, the stability and service life of the oil press machine directly affect production output and oil quality. Proper maintenance not only extends the service life of oil presses but also effectively reduces failure rates and improves production efficiency.

Regularly clean up debris

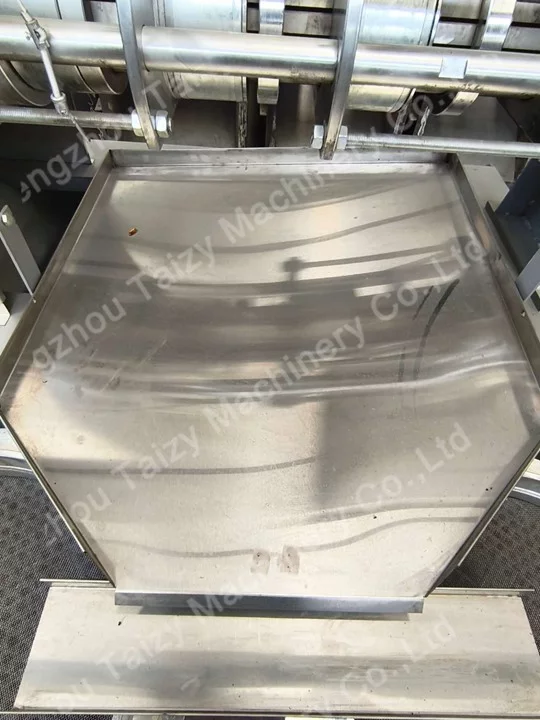

During the oil pressing process, oil residue left in the pressing chamber can easily cause blockages, corrosion, or even damage to the machine if not cleaned promptly.

It is recommended to clean the pressing chamber, filter screen, and other components immediately after each use. This is especially important after processing high-viscosity oil, which requires thorough cleaning.

Cleaning steps

- Turn off the power and wait for the equipment to cool down completely.

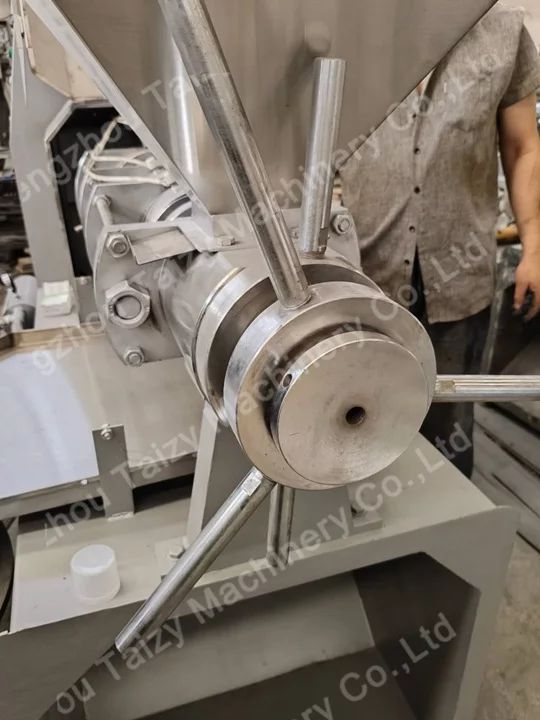

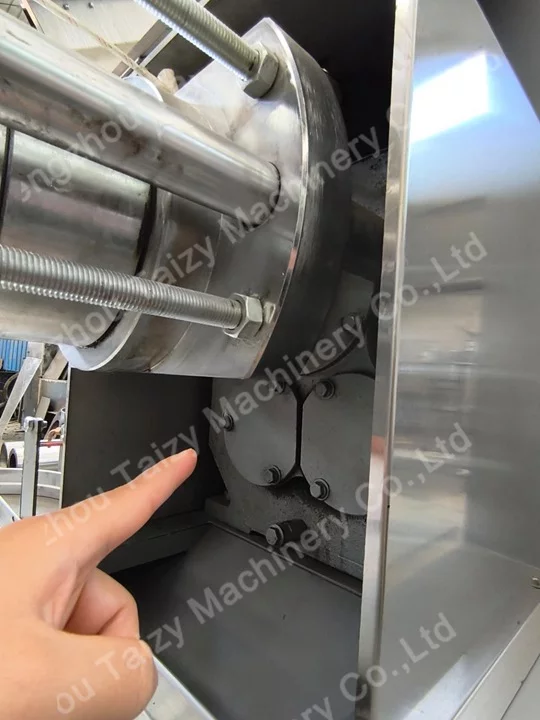

- Disassemble the screw press, screw chamber, and other components in order.

- Use warm water and a soft brush to remove oil stains and residue.

- Reassemble after thoroughly drying.

Lubrication must be adequate

The transmission system, gears, bearings, and other components of the oil press require regular lubrication to reduce mechanical wear.

It is recommended to use genuine lubricants in accordance with the intervals specified in the manual. Do not use inferior or incompatible lubricants.

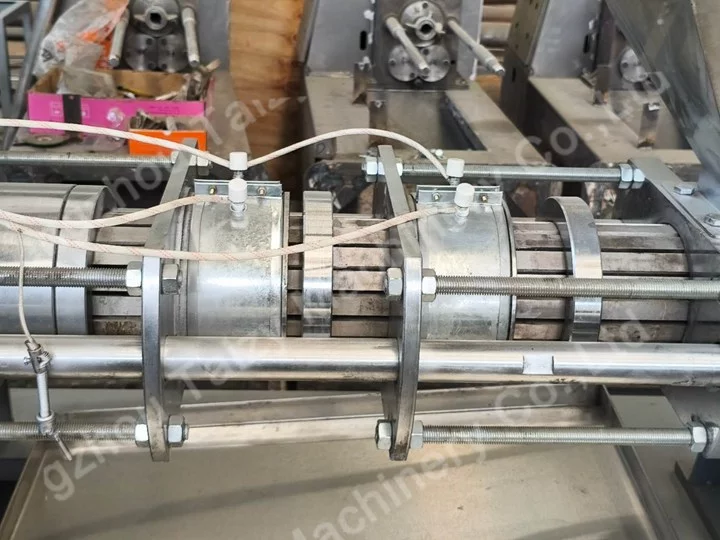

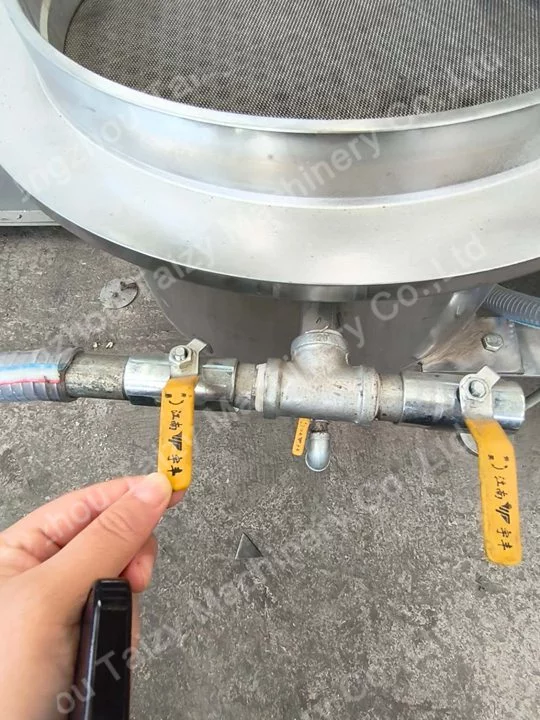

Lubrication point inspection

- Bearing parts: inspect the lubrication condition of bearings monthly and replenish grease promptly.

- Transmission system: regularly inspect the gearbox oil level and replace the lubricating oil as specified.

- Screw shaft: maintain proper lubrication to prevent excessive wear.

Check the circuitry and motor

Regularly inspect power cables, motor operating status, and control panels to promptly identify and replace aging or damaged cables. Ensure adequate motor cooling to prevent burnout caused by high temperatures or unstable voltage.

Inspection frequency

Daily inspection: appearance, sound, temperature abnormalities

Weekly inspection: bolt tightness, belt tension

Monthly inspection: electrical connections, safety device functionality

Operate reasonably to avoid overloading

Operators must undergo professional training and strictly follow operating procedures when using oil presses.

Avoid overloading the machine or frequently starting and stopping it. Incorrect operation can accelerate machine wear and tear and even cause safety accidents.

Regular maintenance and replacement of wear parts

Components such as screw presses, cake rings, and oil rings are subject to wear and tear and should be inspected regularly for wear and replaced on time.

Establishing equipment records and documenting maintenance and replacement cycles can help identify potential issues in advance.

Conclusion

An oil press is a long-term investment, and proper maintenance will greatly enhance the value of the equipment and extend its service life.

We recommend that users strictly follow the maintenance schedule. If you encounter any technical issues, please contact our professional technical staff. Only through careful maintenance can the oil press create greater value for you.