Soybean oil, as one of the world’s most widely consumed vegetable oils, holds immense market potential and profit margins. For investors seeking to enter this industry, establishing an efficient, scientifically designed mechanized production line is the cornerstone of success.

A common question arises: “Can I directly feed soybeans into the oil press?”

The answer is no. To maximize oil yield and enhance the value of the byproduct soybean meal, a complete soybean oil production line requires a scientifically designed pretreatment process.

Why is preprocessing crucial?

Before delving into specific equipment configurations, two points must be clarified:

Dehulling: soybean hulls contain minimal oil. Failure to dehull reduces oil yield, causes equipment wear, and degrades meal quality.

Roasting: this is the key to boosting oil yield! Heating and conditioning disrupts the oil cell structure of soybeans, preparing them for optimal pressing.

Standard configuration for a high-efficiency soybean oil extraction line

A complete, high-efficiency production line typically consists of the following core components:

Step 1: cleaning

Core equipment: cleaning screen, stone remover

Purpose: cleaning equipment removes impurities such as stones, soil, and stems/leaves through screening and air separation. This not only ensures oil purity but also serves as the first line of defense against damage to subsequent expensive equipment.

Step 2: dehulling and cracking

Core equipment: soybean dehulling machine and cracker

Purpose: this equipment first cracks soybeans into several pieces, then separates the lighter hulls from the heavier kernels via an air system. After this step, you obtain pure, high-oil-content cracked kernels.

Step 3: roasting

Core equipment: soybean roaster

Purpose: the cracked kernels are heated in the roaster to achieve optimal moisture and temperature for pressing. This process “activates” the oil, boosting oil yield by 5%-8% and significantly improving meal quality.

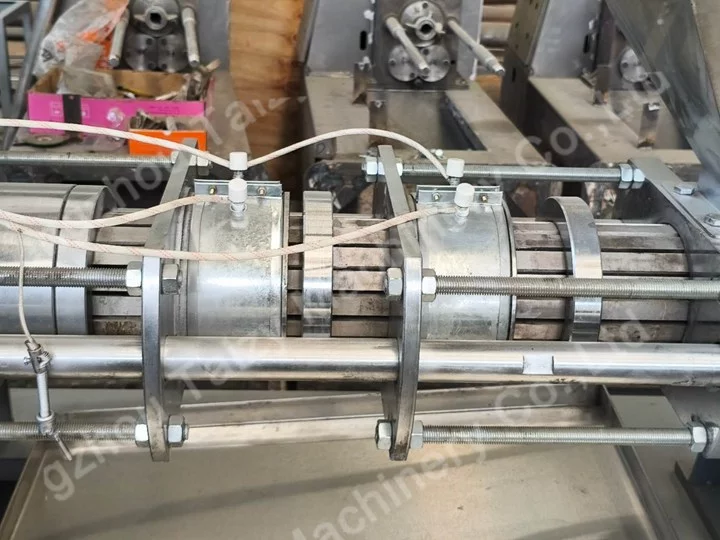

Step 4: oil pressing

Core equipment: screw oil press

Purpose: perfectly pretreated kernels are fed into the oil press. Under intense physical compression, soybean oil is continuously extracted and separated from the solid soybean meal. Selecting a high-yield, stable oil press is crucial.

Step 5: filtration

Core equipment: plate-and-frame oil filter or pneumatic oil filter

Purpose: freshly pressed crude oil contains oil residue. The filter pumps the crude oil under high pressure through specialized filter cloths, achieving precise filtration to produce clear, transparent primary finished oil.

Why is Taizy’s soybean oil extraction line your best choice?

High oil yield: a scientifically designed pretreatment process ensures every ounce of raw material is fully utilized.

High-quality output: you gain not only premium soybean oil but also high-protein, low-fiber soybean meal—a valuable byproduct that generates significant revenue.

Automation and cost efficiency: the entire line operates continuously with minimal manual oversight, drastically reducing long-term labor costs.

Reliability and durability: rational process configuration guarantees stable operation and extended service life.

Conclusion

Investing in the soybean oil extraction industry and selecting the right equipment configuration is half the battle won. A complete production line encompassing cleaning, hulling, steaming and roasting, pressing, and filtration provides the scientific assurance for achieving high efficiency and high returns.

Contact our experts today to receive a customized soybean oil extraction production line solution and a detailed quotation tailored to your output requirements!