In sunflower oil production, one of the most common concerns for manufacturers is the amount of residual oil left in the pressed cake. Excessive oil residue not only reduces overall extraction efficiency but also directly impacts the profitability of your production line.

If you’re using a sunflower oil press machine, optimizing the pressing process is essential to achieve higher oil yield and lower residual oil rate.

So, what factors affect oil residue after pressing sunflower seeds?

Proper Seed Pretreatment Is Essential

Before sunflower seeds enter the oil press machine, they must undergo proper pretreatment steps, such as:

- Cleaning

- Drying

- Roasting

Removing impurities and adjusting the moisture content helps improve oil flow during pressing. A uniform roasting temperature can soften the oil cells inside the seeds, allowing the sunflower oil press machine to extract oil more efficiently.

Control Moisture Content of Sunflower Seeds

The moisture level of sunflower seeds plays a crucial role in pressing performance.

- If the moisture is too high → pressing becomes inefficient

- If the moisture is too low → seeds become brittle

The ideal moisture content ensures that the sunflower oil press machine can maintain optimal pressing pressure without clogging or excessive cake formation.

Adjust Pressing Temperature

Temperature directly affects oil viscosity.

Preheated seeds entering the oil press machine allow the oil to flow more smoothly, reducing resistance during the pressing process and lowering the oil content left in the sunflower cake.

Many modern sunflower oil press machines are equipped with automatic temperature control systems to maintain consistent pressing conditions.

Optimize Pressing Pressure

Insufficient pressing pressure often results in high oil residue.

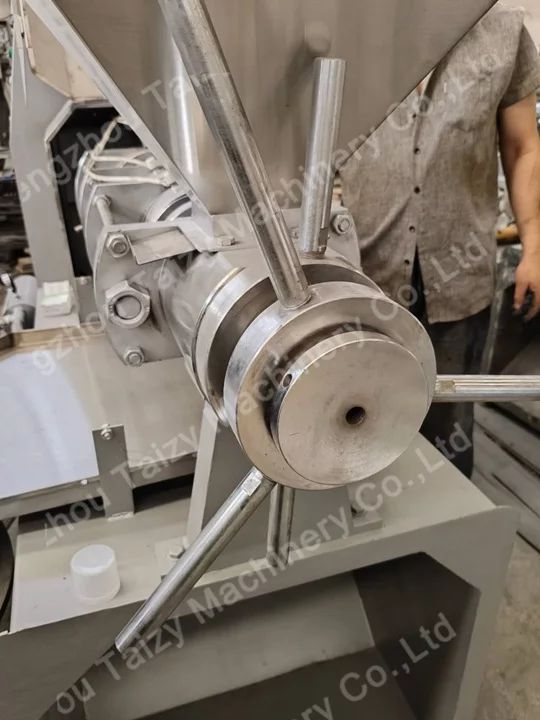

Industrial-grade sunflower oil press machines with stable hydraulic or screw pressing systems can:

- Increase oil extraction rate

- Reduce residual oil in the cake

- Improve production efficiency

Maintaining consistent pressure ensures maximum oil recovery from each batch of sunflower seeds.

Use a Multi-Stage Pressing Process

For higher-capacity operations, a two-stage pressing process can significantly reduce oil residue.

Using a primary oil press machine followed by secondary pressing helps extract remaining oil from the cake, improving overall oil yield without chemical extraction methods.

Regular Maintenance of Oil Press Equipment

A poorly maintained sunflower oil press machine may lead to:

- Uneven pressure distribution

- Reduced pressing efficiency

- Higher oil residue

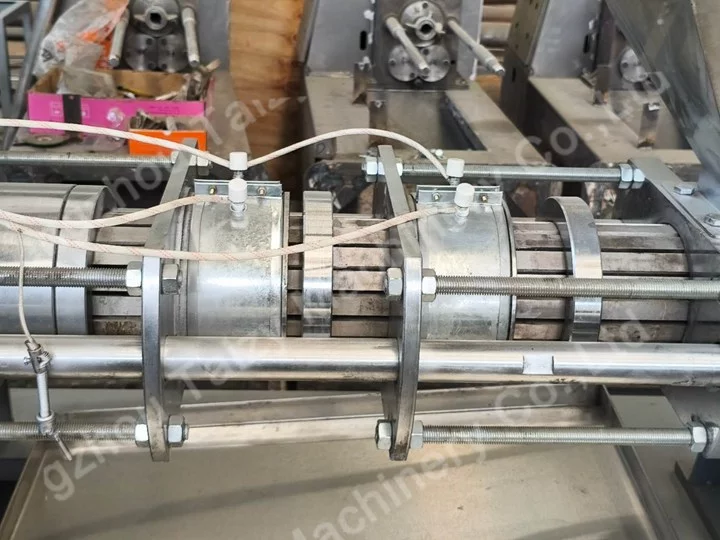

Routine inspection of pressing components such as screws, barrels, and hydraulic systems helps maintain optimal performance.

Why Choose Our Sunflower Oil Press Machine?

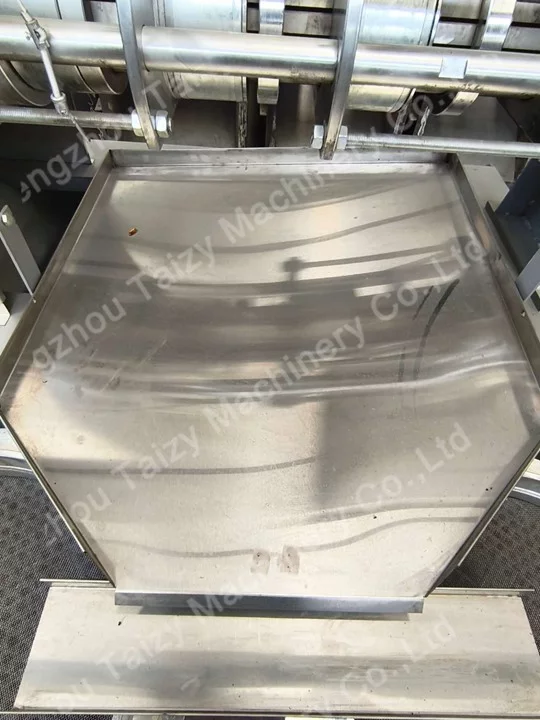

Our advanced sunflower oil press machine is designed to deliver:

- Stable high-pressure pressing

- Low residual oil rate

- Efficient temperature control

- Continuous operation capability

- Durable food-grade construction

- Energy-saving performance

With our industrial oil press machine, you can significantly improve sunflower oil extraction efficiency while reducing operational costs.

Improve Your Oil Yield Today!

If you’re looking to minimize oil residue and maximize profitability in sunflower oil production, investing in a high-performance sunflower oil press machine is the key.

Contact us today to get a customized oil pressing solution and the latest quotation!