Recently, our company successfully exported a hydraulic oil press to Togo, Africa, to provide key production equipment for a newly built oil press plant there. The customer is mainly engaged in the vegetable oil processing industry.

The hydraulic oil press purchased this time is used together with the almond shelling machine purchased from our factory to realize the integrated process from raw material pre-treatment to oil extraction.

After the equipment was put into production, the customer’s feedback was that the production efficiency was greatly improved and the oil quality was stable, which effectively helped the customer to expand the local market and gain considerable economic benefits.

Client background

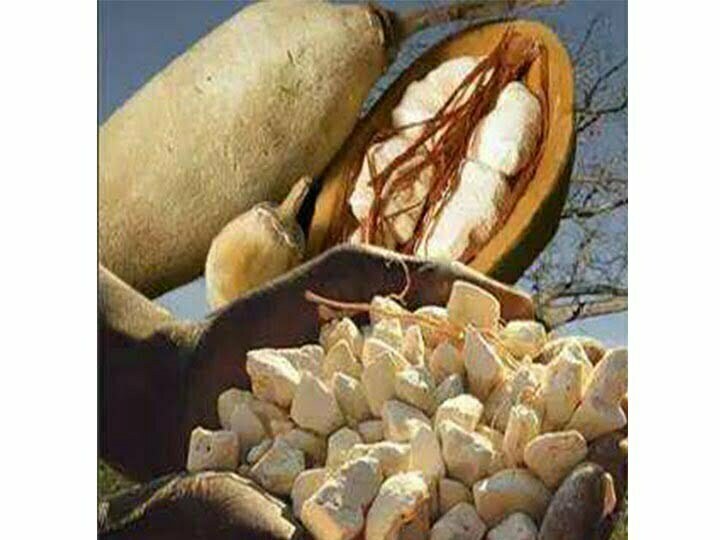

The client is located in the southern region of Togo, which is situated in the tropical agricultural resources belt and is rich in oil crops such as palm nuts, almonds, and peanuts.

In recent years, the local market demand for vegetable oil has been increasing year by year. In addition, the customer has a stable almond purchase channel, so he decided to invest in a small oil press plant, specialising in processing local almonds and palm fruits, in order to realise the value-added of the raw materials locally.

When purchasing the oil press equipment, the customer pays special attention to the oil yield, ease of operation, and energy consumption, and strives to achieve stable operation at the early stage of production.

Customised solutions

According to the actual needs of customers, our company recommended the compact structure, high oil yield, and easy maintenance output in the 50kg hydraulic oil press model. We also provide customers with an almond shelling machine to form a complete pretreatment and oil extraction process.

For the customer’s first time setting up a factory, we also provide the operation process video, equipment layout suggestions, and electrical wiring diagrams, to help the customer successfully complete the preparatory work from the construction of the plant to the start of production. In addition, the low noise and trouble-free characteristics of the hydraulic oil presses also meet the local requirements for low power stability.

Why choose Taizy?

During the whole cooperation process, we fully demonstrated our company’s professional strength in equipment export service.

From the completion of the production of equipment, we took the first time to shoot a detailed test video and packaging photos to ensure that the customer can conduct a remote inspection without worry.

The packaging of the equipment adopts the double reinforcement of thickened laminating film + customised wooden case, which is moisture-proof and collision-proof to ensure that the equipment arrives at the destination safely.

Before shipment, we also remotely connect with the customer via video phone to confirm the status of the equipment on site and enhance the customer’s confidence.

Positive customer feedback

After the equipment arrived in Togo, our company arranged professional technicians to guide the customer to complete the installation and debugging by remote video, and taught the operation skills and maintenance methods hand in hand.

The customer was highly satisfied with our service, praising the smooth operation of the equipment, high oil output rate, and the quick learning curve of the workers, which greatly improved the overall production capacity and efficiency of the factory.

At present, the customer is planning to expand the production line, and expressed the willingness to continue long-term cooperation with our company, purchasing more processing equipment to meet the growing market orders.

So what are you waiting for? Feel free to contact us if there is a corresponding need!