Peanut screw oil presses are widely popular due to their high oil extraction rate, high degree of automation, and suitability for large-scale oil mills. However, common malfunctions inevitably occur during actual operation. If not addressed promptly, these issues not only reduce oil extraction efficiency but may also shorten the machine’s lifespan.

This article will outline common operational problems encountered with peanut oil presses and their corresponding solutions.

Oil yield decrease

Common causes:

Peanut moisture content is too high or too low

Insufficient chamber temperature

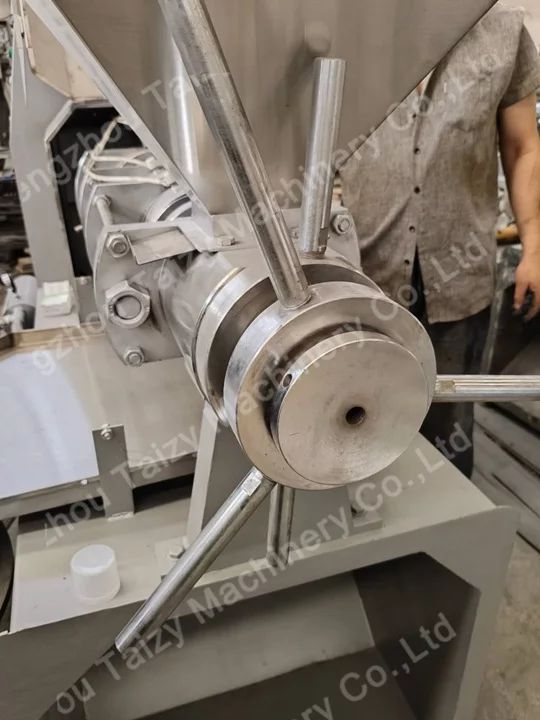

Severe screw wear

Solutions:

Maintain peanuts at appropriate moisture content (6%–8%)

Thoroughly preheat the chamber before startup

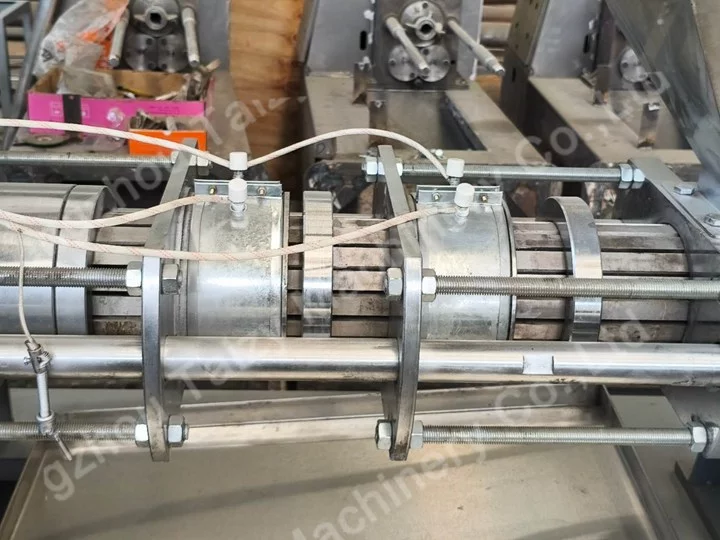

Regularly inspect and replace worn screws and press bars

Machine malfunction or abnormal noise

Common causes:

Inadequate removal of impurities from peanuts causes hard objects to enter the crushing chamber

Lack of lubrication or damage to bearings

Poor screw conveyor operation

Solutions:

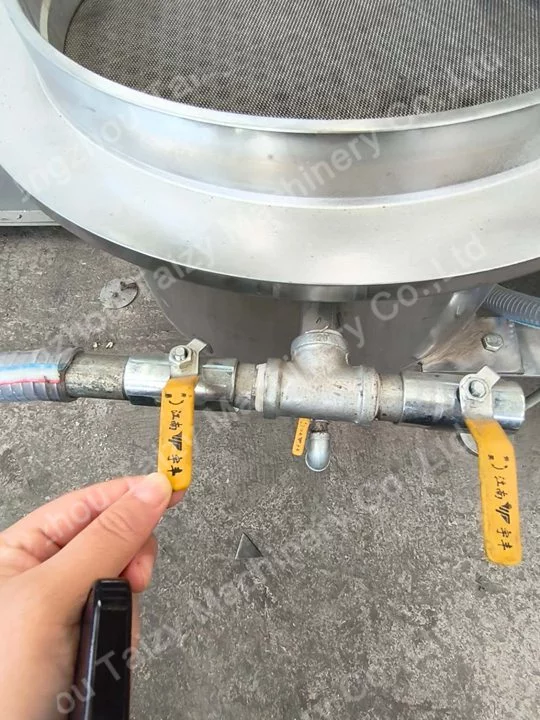

Thoroughly clean raw materials before use to remove impurities such as stones and metal fragments

Regularly apply lubricating oil; replace bearings when necessary

Adjust screw clearance to prevent jamming

Excessive oil residue content

Common causes:

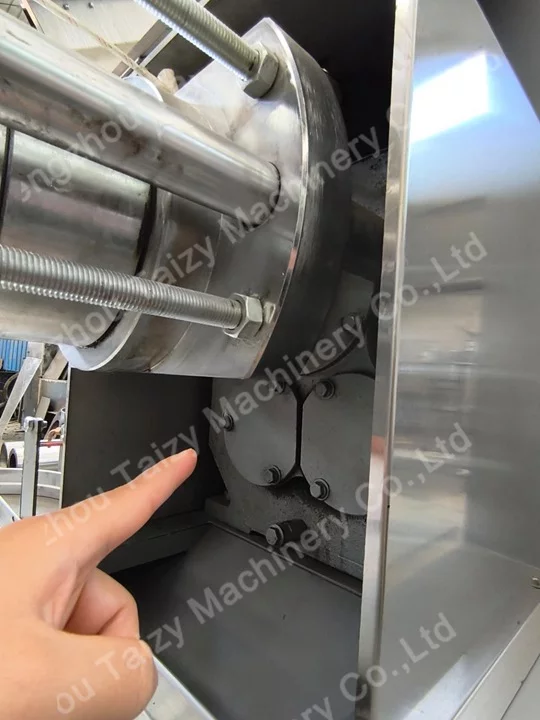

Excessive gap between press rollers

Damaged or clogged filter screen

Incomplete shell removal from

raw material

Solutions:

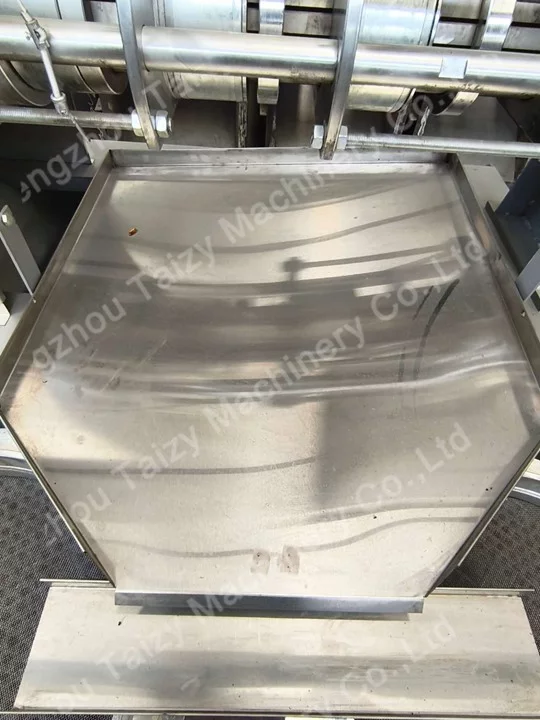

Adjust roller gap to maintain uniform pressure

Regularly clean or replace the filter screen

Improve the peanut shelling rate to ensure effective pressing

Motor overheating or insufficient power

Common causes:

Prolonged operation under overload conditions

Unstable voltage supply

Motor aging

Solutions:

Schedule workloads appropriately to avoid extended high-load operation

Ensure stable power supply; install voltage stabilizers if necessary

Conduct regular motor inspections and perform timely maintenance or replacement

Advantages of using the Taizy peanut oil press

High oil yield: spiral pressing design is ideal for large-scale production in peanut oil mills.

Easy operation: high automation allows operation by just 1-2 people.

Versatile: not only presses peanuts, but also suitable for sesame, soybeans, sunflower seeds, and other oilseeds.

Summary

Malfunctions in peanut oil presses during production are inevitable. However, understanding the causes of common issues and their solutions can effectively reduce downtime and enhance oil extraction efficiency. Regular maintenance and proper operation are key to ensuring the stable performance of the oil press.

If you are seeking a high-efficiency, durable peanut oil press, please contact us for professional equipment and solutions.