The dream of producing your own pure, golden olive oil is a powerful one. Whether you’re a small-scale farmer, a boutique producer, or a passionate hobbyist, the heart of your operation is the press. The hydraulic olive oil press, known for its ability to produce the highest quality cold-pressed extra virgin olive oil, is often the top choice.

But with various models and specifications, how do you choose the right one? Making the wrong choice can lead to inefficiency and frustration, while the right machine will be a reliable partner for years to come.

This guide provides a clear, checklist-style approach to help you select the perfect hydraulic olive oil press for your specific needs.

Checklist Item 1: Match the Tonnage and Capacity to Your Harvest

The “tonnage” of a press refers to the amount of pressure it can exert. However, for practical purposes, you should focus on the batch capacity, which is how many kilograms of olive paste the machine can press at one time.

For small-scale and hobbyist production: if you are processing olives from a small grove for personal use or for sale at a local farmer’s market, a machine with a capacity of 10-30 kg per batch is likely a perfect fit. It allows for manageable production without significant waste.

For small commercial operations: if you are running a small commercial business, supplying local restaurants, or have a larger harvest, look for a machine with a capacity of 40-60 kg per batch or more. This allows you to process your harvest efficiently during the critical, time-sensitive pressing season.

Pro-tip: it’s better to run multiple batches on a correctly sized machine than to under-fill a machine that is too large, which can lead to inefficient extraction.

Checklist Item 2: Measure Your Space: Footprint and Layout

A hydraulic press is a substantial piece of equipment. Before you fall in love with a model, get out your measuring tape.

Machine dimensions: check the machine’s length, width, and height. Ensure it will not only fit in your designated space but also pass through any doorways or gates to get there.

Working area: remember to plan for workspace around the machine. You’ll need room to comfortably load the olive paste, position the collection container for the oil, and remove the spent olive pomace.

Vertical design advantage: most hydraulic olive oil presses feature a vertical design, which makes them very space-efficient. They have a relatively small footprint, making them ideal for workshops, garages, or small processing facilities where floor space is at a premium.

Checklist Item 3: Prioritize Simplicity and Ease of Operation

Your time is valuable. You need a machine that works with you, not against you. A complex, intimidating machine will slow you down.

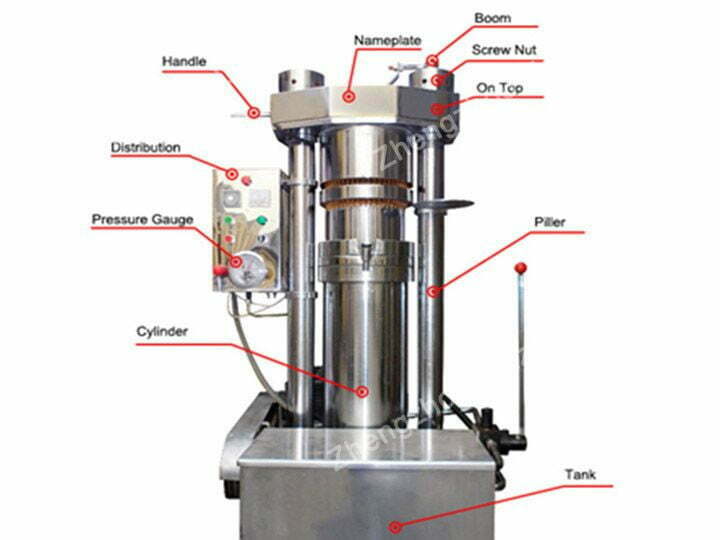

Clear controls: look for a press with a simple, intuitive control panel. A clear pressure gauge and straightforward start/stop buttons are essential.

Easy loading and unloading: the design of the pressing cage or barrel should be easy to access. Models with a wheeled base for the barrel and pressing plates make loading and unloading significantly faster and less physically demanding.

Automated pressure: a key feature of modern hydraulic presses is their ability to automatically manage pressure. You set it, and the machine does the work, stopping when the process is complete. This ensures consistency and frees you up to perform other tasks.

Checklist Item 4: Don’t Overlook Cleaning and Maintenance

In food production, hygiene is non-negotiable. A machine that is difficult to clean is a liability.

Food-grade materials: insist on a press where all parts that come into contact with the olive paste and oil are made from food-grade 304 stainless steel. This includes the pressing plates, collection tray, and barrel. Stainless steel is non-reactive, durable, and easy to sanitize.

Ease of disassembly: check how easily the core components can be taken apart for cleaning. The pressing plates and filter discs should be simple to remove and wash after each day’s use.

Sealed hydraulic system: a well-designed machine will have a fully sealed hydraulic system. This is crucial to prevent any risk of hydraulic fluid contaminating your precious olive oil.

Taizy Hydraulic Olive Oil Press: Designed for Quality and Simplicity

Choosing your first press is a significant step, and we’ve designed our machines to make that choice an easy one. Our hydraulic olive oil presses are built with the boutique producer and small-scale farmer in mind, perfectly aligning with every point on the checklist above:

- Versatile capacities: we offer a range of models to perfectly match your harvest size.

- Space-saving design: our compact, vertical presses fit easily into most workshops.

- User-friendly operation: with automated pressure control and an intuitive interface, our machines are incredibly easy to operate, even for a beginner.

- Uncompromising hygiene: we use only food-grade 304 stainless steel for all contact parts, and our sealed hydraulic system guarantees the purity of your oil.

We believe that producing exceptional olive oil should be a joy, not a struggle. Our machines are engineered to be your reliable, efficient, and easy-to-clean partner for many harvests to come, empowering you to turn your olives into liquid gold with consistency, purity, and pride.

Ready to find the perfect hydraulic press for your olive harvest? Contact our experts today for a personalized consultation and a detailed quote. Let’s start your olive oil journey together!