How to quickly build a premium peanut oil brand in the market? A customer in Pakistan successfully established a local high-end peanut oil brand by introducing our peanut oil screw extraction, which has a production capacity of 50-80 kg/h.

Customer background and requirements

The customer is located in the main peanut production area near Punjab Province, Pakistan, where seasonal peanut purchase prices are relatively stable and raw materials are readily available.

Local traditional processing methods are mostly simple pressing in small workshops or outsourcing, which has the following problems:

- Large fluctuations in oil yield

- Excessive oil temperature results in an impure aroma and a dark color

- Lack of uniform hygiene and packaging standards

The customer originally engaged in agricultural product trading, possessing stable raw material collection channels and a regional small-scale wholesale network. However, the existing equipment was inefficient and had unstable oil yield, making it difficult to meet the growing market demand.

Its core requirements:

The equipment must be suitable for medium-scale start-ups, with a single shift daily processing capacity of 0.4–0.6 tons of raw materials. It should be capable of hot pressing to enhance oil extraction rates, while also allowing for low-temperature cold pressing in certain batches to create differentiation.

The solutions we offer

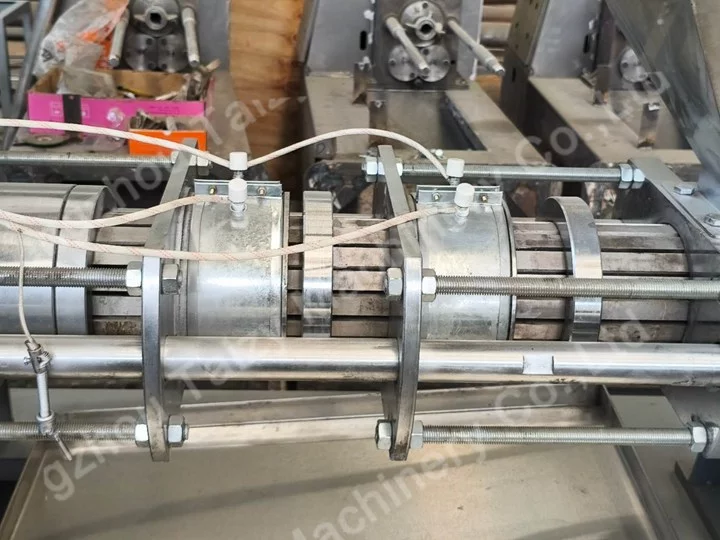

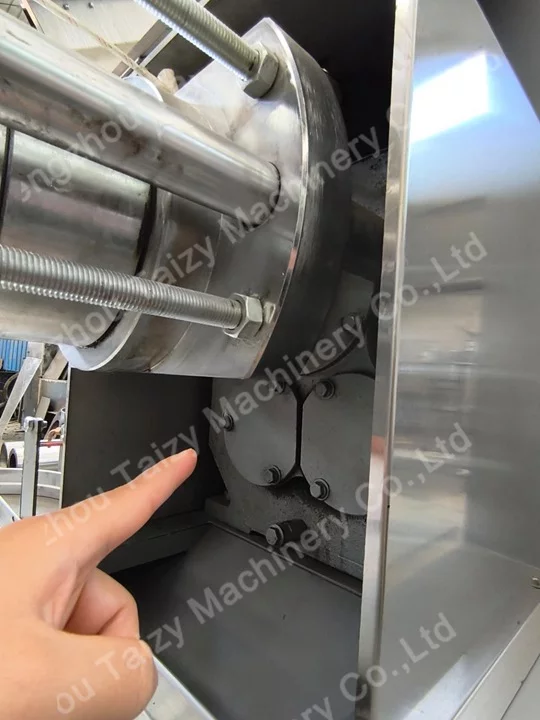

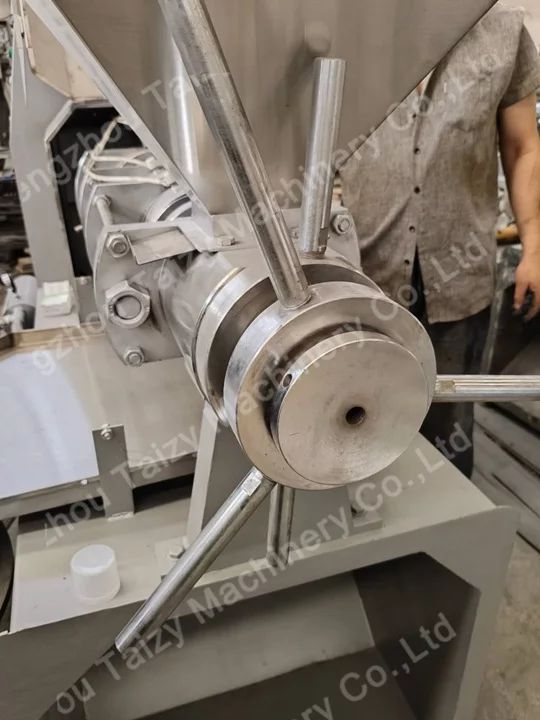

Based on the customer’s requirements, we customized a 50-80kg/h peanut oil screw press for them. It is equipped with a feed and oil discharge system to optimize pressing efficiency.

At the same time, we customized the voltage and plugs based on the customer’s site and power conditions to ensure that the equipment can be put into production immediately upon arrival.

Advantages of Taizy peanut screw oil extraction

- High adaptability: standard setup handles peanuts, sesame, sunflower, and more—one machine, multiple oils.

- Higher yield, low residue: optimized spiral keeps peanut cake residual oil around 6–8%.

- Easy to use and maintain: quick-disassembly spiral and outlet; daily cleaning faster; safety guard + emergency stop.

- Ready to expand: interfaces reserved for filters, screening units, and semi-auto filling later.

- Low energy consumption, simple operation, suitable for continuous production in small and medium-sized factories.

Taizy’s comprehensive services

- Raw material test video: peanut trial shows oil flow and cake strips for intuitive evaluation.

- Protective packaging: moisture-proof film + reinforced wooden crate + anti-slip pads for sea freight.

- Pre-shipment video inspection: live check of serial numbers, electrical panel, running test, vibration, and noise.

- Complete documents: equipment list, operating manual, wiring diagram, maintenance schedule.

- After-sales support: dedicated chat group for fast consumables and technical responses.

- Quality traceability: serial and batch records simplify future upgrades or expansions.

Customer feedback and results

After the equipment arrived at the port and cleared customs, our remote engineers guided customers through machine installation and trial operation via video. The machine was run at a low feed rate for the first two days to break it in, and reached a stable range on the third day.

By fully utilizing local peanut resources and matching them with a 50–80kg/h screw oil press that is suitable for the production range, the customer successfully upgraded from raw material trading to a high-value-added edible oil brand.

If you also wish to transition from “small-scale production” to “premium quality,” please contact us to obtain customized solutions, trial machine videos, and process parameters.