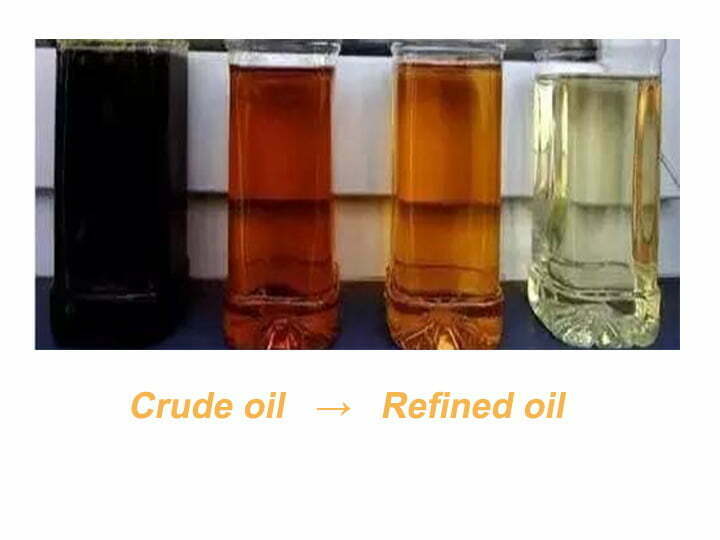

Cooking oil refinery machine is designed to refine crude edible oil, preliminarily extracted from oil crops. The refined oil is of high quality, free from harmful impurities and meets the national quality standard of edible oil. After refining process, the water content, impurities, acid value and peroxide value of crude oil meet the quality standards, so it is not easy to deteriorate and can be stored for a relatively long time. The refined oil maintains the oil flavor and does not produce a large amount of oil smoke in cooking. As a professional oil refinery equipment manufacturer, we provide small and large types oil refining equipment and high-quality supporting services. Our refined oil equipment has wide application, suitable for peanut oil, soybean oil, corn oil, walnut oil, palm oil, tea seed oil, etc. and has been exported to a great number of countries in Central America, Latin America, Southeast Asia, Africa, etc.

Scope of application

Our oil refinery machine can be used for refining crude peanut oil, soybean oil, corn oil, walnut oil, palm oil, cottonseed oil, coconut oil, tea seed oil, sunflower seed oil, flaxseed oil, pepper seed oil, etc.

Working process of cooking oil refinery machine

Generally, crude palm oil needs to be filtered by air pressure oil filter before refining process.

This oil refining machinery has the functions of degumming, deacidifying, decoloring, deodorizing and dewaxing. It contains oil refining tanks and other supporting equipment, including measurement device, automatic temperature control device, adiabatic device and material buffer device.

Degumming

In the degumming process, the oil refinery machine rinses the raw oil with hot salty water.

Deacidification

Mix the alkali water from the alkali water tank into the crude oil. Actually, degumming and deacidification are carried out simultaneously, which is expected to take 5-6 hours.

Decolorization

Add active white clay into the crude oil to adsorb pigments and impurities. The initial temperature in the tank is 110 ℃, and it takes 30 minutes to cool down to 70 ℃. This procedure needs about 1 hour.

Deodorization

Deodorization is a process that removes substances affecting oil odor based on the difference of volatility under high temperature and vacuum. In the process, the equipment adopts the principle of steam distillation. The temperature in the tank is 220-260 ℃. Steam is introduced to extract the substances affecting the oil smell from the crude oil. The process lasts for 4 hours.

Dewaxing

Because the newly extracted crude oil contains a certain amount of wax, it needs to be dewaxed by fractionation (heating and crystallization method). Thus, it can produce finished product of palm oil, palm olein, palm stearin etc.

Cooking oil refinery equipment structure details

The main parts of the cooking oil refinery machine include a hot water and alkali water tank, oil injection pump, refining tank, decolorization tank, white clay pot, gas separator, deodorizing tank, refined oil pump, deodorization tank, vacuum pump, corridors for observation.

| Oil pump |  | Hot water and alkali water tank |  |

| Refining tank |  | Hot water tank |  |

| Decolorization tank |  | Deodorant pot |  |

| Gas-liquid separator |  | Steam superheater |  |

Oil grades and main processing steps

| Oil grade | Number of tanks | Processing steps | Duration |

| Third-grade oil | 2 or 3 | degumming, deacidification | 6-8h |

| Second-grade oil | 4 | degumming, deacidification, decolorization, deodorization | 12h |

| First-grade oil | 4 or 5 | degumming, deacidification, decolorization, deodorization, (dewaxing) | ≥12h |

Features of edible oil refinery machinery

- The edible oil refinery machine adopts stainless steel and it is polish.

- Simple design, exquisite appearance.

- The operation is simple and safe. The operation data is automatically displayed.

- Integrated operation. The cooking oil refining machine can realize all the functions of degumming, deacidification, decolorization, and deodorization of oil products.

- The refined oil is pure and with bright color. It is of high quality. The processed oil can reach fourth grade to first grade.

- Multiple capacities. We offer different outputs of oil refinery machine and support customization service.

- Wide application. It can refine a variety of crude cooking oil, like peanut oil, sesame oil, rapeseed oil, palm oil and sunflower seed oil.

Small scale edible oil refinery machine

The small cooking oil refinery machine is suitable for small-scale oil mills or plants. It is specially designed for small oil refining and oil-refining complete sets of units, and realizes degumming (dehydration, dephosphorization), deacidification, decolorization, deodorization, thus achieving large-scale refinery miniaturization and industrial refining and civilian use. The refined oil can reach the level of edible oil of the second grade or above, and can be filled and sold for direct use. The refined oil equipment is suitable for refining various crude edible oil, such as peanut oil, sesame oil, sunflower seed oil, rapeseed oil, palm oil.

Outstanding features

- This machinery can achieve integrated assembly operation of dephosphorization, degluing, decolorization, and dehydration.

- Refined oil is of good quality, clear and bright.

- High processing efficiency. The output of small oil refinery equipment reaches up to 500kg per day.

- Simple operation and labor-saving

Part of small scale oil refinery machinery parameter

| Model | TZ-50 | TZ-75A | TZ-75B |

| Capacity | 30kg/h | 100kg/h | 130kg/h |

| Motor Power | 1.5kw | 3kw | 4.5kw |

| Power | 5kw | 10kw | 15kw |

| Number of tanks | 1 | 2 | 3 |

| Volume | 75kg | 250kg | 250kg |

| Diameter | 500mm | 750mm | 750mm |

| Weight | 140kg | 280kg | 350kg |

| Dimension | 1500*680*1400mm | 3000*830*1700mm | 3900*830*1700mm |

| Model | TZ-300-2 | TZ-300-3 |

| Capacity | 500kg/day | 750-1000kg/day |

| Electric heating power | 9kw x 2 | 9kw x 3 |

| Mixing motor | 0.75kw x 2 | 0.75kw x 3 |

| Vacuum pump motor | 2.35kw | 2.38kw |

| Voltage | 380V | 380V |

| Tank thickness | 3mm-4mm | 3mm-4mm |

| Tank diameter | 700mm | 700mm |

| Tank volume | 300L | 300L |

| Total weight | 560kg | 960kg |

| Dimensions | 2600 * 1000 *2300mm | 3600*1000*2300mm |

| Material | stainless steel | stainless steel |

Large oil refinery equipment

Large-scale cooking oil refinery machine can achieve continuous and fully automatic operation, often used in medium or large oil refining factories. It is featured with high refining efficiency, high automation and large output. The capacity of large oil refinery machinery can reach 1 ton to 10 tons per day. The heating source is usually heat conducting oil.

Technical data of large type oil refinery equipment

| Model | TZ-500-2 | TZ-500-3 |

| Capacity | 1000kg/8h | 1500kg/8h |

| Electric heating power | 18kw x 2 | 18kw x 3 |

| Mixing motor | 1.5kw x 2 | 1.5kw x 3 |

| Vacuum pump motor | 3.85kw | 3.85kw |

| Voltage | 380V | 380V |

| Tank thickness | 3mm (refiningtank); 5mm (vacuum tank) | 3mm (refiningtank); 5mm (vacuum tank) |

| Tank diameter | 850mm | 850mm |

| Tank volume | 500L | 500L |

| Total weight | 850kg | 1320kg |

| Dimensions | 3000*1000*2600mm | 4000 * 1000 *2600mm |

| Material | stainless steel | stainless steel |

Video of cooking oil refining machine

If interested, feel free to contact us directly.