Peanut oil is very popular among consumers because of its strong flavor and rich nutrients. For small and medium-sized factories that want to invest in the peanut oil business, choosing an efficient, stable, and cost-effective peanut oil press line is the key to realizing quick profits.

However, in the face of many equipment and technologies, how to select the right production line for you has become a difficult problem for many enterprises. In this article, we will start from the function and advantageous features of the equipment, to provide you with a guide to choose and buy a peanut oil press production line.

Demand for characteristics of small and medium-sized oil extraction lines

Small and medium-sized factories are relatively limited in terms of budget, space and labor. Therefore, it is suitable to choose a combination of equipment with a moderate degree of automation, convenient operation and easy maintenance.

In addition, the equipment should have good scalability, so that the production line can be upgraded when production volume increases in the future.

How to choose the peanut oil press line suitable for small and medium-sized factories?

When choosing a peanut oil extraction line, small and medium-sized factories should focus on the following aspects:

- Matching production capacity

Choose the right production line according to the size of the factory and market demand. Small and medium-sized factories are recommended to choose equipment with a small footprint and low energy consumption to reduce operating costs.

- Degree of equipment automation

A production line with a high degree of automation can significantly improve production efficiency while reducing labor involvement and lowering labor costs.

- Equipment quality and durability

Oil press equipment needs to be durable and stable. Choosing equipment with good materials and mature technology can reduce the failure rate and maintenance costs.

- Oil yield and oil quality

The oil yield of the oil press machine directly affects the production profit. It is especially important to choose the equipment that has a high oil yield and can guarantee the quality of oil products.

- After-sales service and technical support

Choose the equipment supplier that provides perfect after-sales service and technical support to ensure that the equipment can be resolved promptly when problems arise in the course of use.

Main equipment of the peanut oil extraction line

Peanut oil pressing production line usually consists of the following parts, and each part of the equipment has its unique function:

Peanut shellers: the key to front-end processing

A peanut sheller can efficiently remove peanut shells to improve the quality of subsequent roasting and pressing.

Taizy’s peanut sheller adopts the roller shelling structure, with a clean shelling rate of up to 98%, which is suitable for continuous operation, and automatic screening of impurities, which helps to improve the efficiency of the whole line.

Peanut roasters: a critical step in improving oil yield

After shelling, peanuts need to be roasted evenly to enhance oil activity.

Taizy offers electric or gas peanut roasters with a multi-temperature control system to ensure that the peanuts are evenly heated to enhance the oil yield while retaining the aroma of the oil.

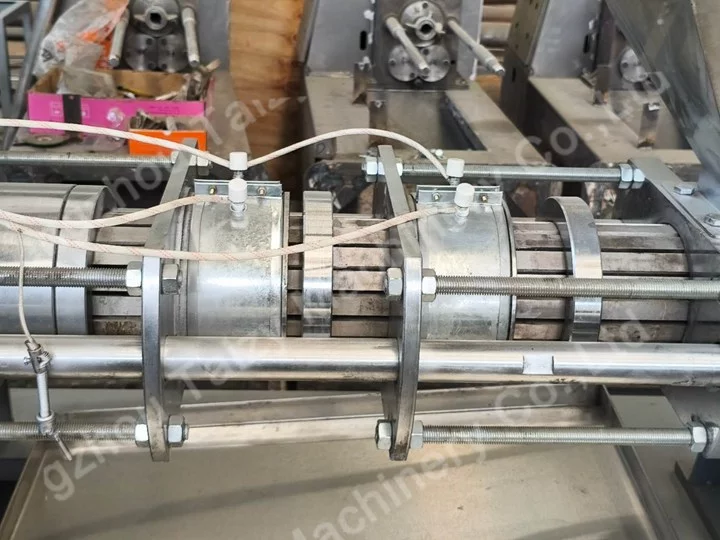

Screw oil press: the core power of the whole line

As the core of the production line, the screw press determines the efficiency and stability of the entire oil production line.

Taizy’s models cover a wide range of small and medium-sized production capacity needs. They utilize alloy screws and wear-resistant pressing chambers, supporting both cold and hot pressing modes. Their compact design and easy cleaning make them particularly suitable for daily, continuous operation in small and medium-sized factories.

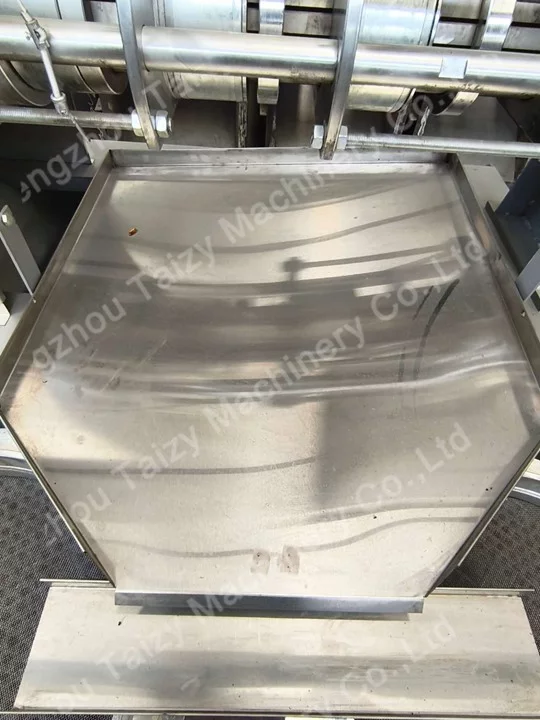

Oil filling machine: improving packaging efficiency

The refined peanut oil is quantitatively packaged by oil oil-filling machine.

Taizy’s liquid filling equipment supports multi-bottle type and multi-size filling. It is equipped with an anti-drip design and a digital quantity control system, which makes the filling speed fast and precise. It greatly improves the efficiency and standardization of product packaging.

Why choose Taizy’s peanut oil press line?

One-stop solution: full set configuration from raw material pretreatment to finished product packaging.

Customized service: customized matching according to plant size and production demand.

Durable and easy to maintain equipment: core components are made of high-quality materials, easy to maintain.

Experienced in international export: we have successful production cases in many countries.

Conclusion

Peanut oil is in high demand, and modernized production lines are the key to competitiveness for small and medium-sized factories.

Taizy provides not only the equipment, but also the total solution. If you are thinking of building or upgrading a peanut oil press line, please contact us for a quote and design.