Peanut oil press production line

The peanut oil production line uses peanut processing machines to process peanuts into the oil. The peanut oil is clean, free of impurities, and of good quality.

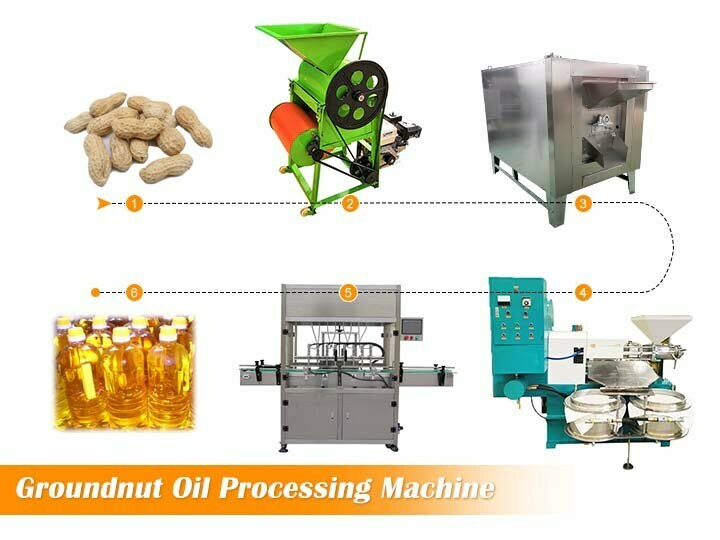

The automatic peanut oil production line processes raw peanuts into peanut oil through automated oil making machines. The groundnut oil squeezed by an automated peanut oil processing machine is clean, free of impurities, and of good quality. The peanut oil pressing line mainly includes a peanut shelling machine, roasting machine, oil press, vacuum oil filter, and oil filling machine. The peanut oil pressing process mainly includes hot pressing and cold pressing. Different processes involve different peanut oil processing plants. If customers have different production processes, we can offer customized services according to their needs.

Peanut oil characteristics

Peanut oil is light yellow and transparent, with bright color and good taste. Groundnut oil is an edible oil that is relatively easy to digest. It contains more than 80% unsaturated fatty acids (including 41.2% oleic acid and 37.6% linoleic acid). It also contains 19.9% saturated fatty acids such as palmitic acid, stearic acid, and arachidonic acid.

Its fatty-acid composition is better, which is easy for the human body to digest and absorb. Groundnut oil can decompose the cholesterol in the human body to reduce the cholesterol content in the blood plasma. The choline in oil can still improve the memory of the human brain and delay the decline of brain function. Peanut oil also contains other substances beneficial to human health.

Groundnut oil Processing line video

Industrial peanut oil production line

Common processes of groundnut oil processing machine mainly include peanut pretreatment, shelling, roasting, oil extraction, vacuum oil filtration, and filling. Each machine of the peanut oil processing line has different types and models to meet various demands.

Groundnut cleaning

Impurities in peanuts will affect the quality of the oil and the quality of the oil cake, and it will also absorb part of the fat. In addition, impurities can also cause wear and tear on peanut processing machines and affect processing results. Therefore, in order to ensure the normal operation of peanut oil extraction, peanuts should be cleaned before oil extraction.

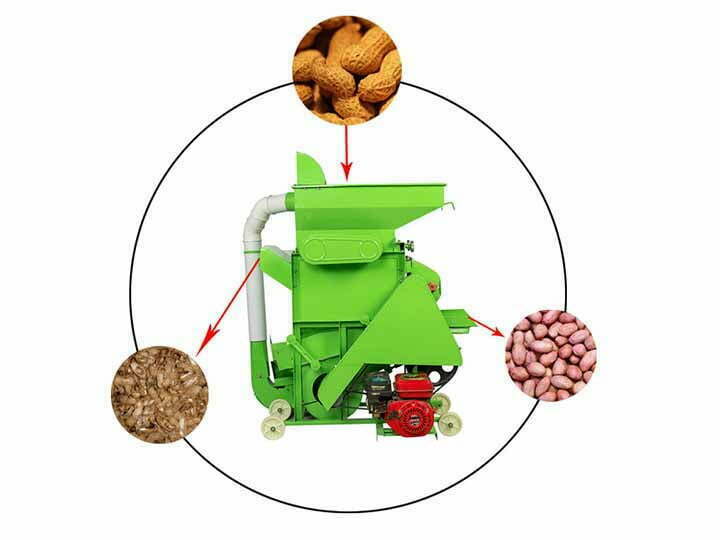

Peanut shelling machine

Model: TZ-800

Capacity: 800kg/h

Shelling ratio: 95%

Clean ratio: 98%

Motor: 4kw

Dimension:1520*1060*1660mm

It has proved that the use of dehulled peanuts by a peanut shelling machine to press oil can reduce the absorption of oil by the shell and increase oil production. The use of shelled peanuts can improve the processing capacity of the oil press and reduce the wear and tear on the groundnut oil press. At the same time, shelled peanuts can also improve the quality of oil cakes. The technical data of TZ-800 is as shown above. The selling and cleaning rate is very high. We provide peanut shelling machines with different outputs.

Peanut roasting machine

Model: TZ -100

Capacity:100kg/h

Motor power:1.1kw

Heating power:18kw

Temperature 0 –300°

The purpose of roasting peanuts by a peanut roaster machine is to remove the water in the peanuts to improve the oil extraction capacity and the quality of the oil cake. The roasting temperature is about 130°C, and the moisture content of the roasted peanuts should be 1~2%. In this way, the oil cake produced after pressing is 0.7~1.2mm. TZ-200 is a popular model of our nut roaster with a single drum. For large output, there are more drums in the machine.

Peanut oil extraction machine

Model: TZ-80A

Screw diameter: 80mm

Capacity: 125-150kg/h

Motor: 7.5kw

The peanut oil extraction machine is the most important machine in the peanut oil processing line. Our company provides various automatic oil press machines. The oil pressing process has two ways: cold pressing and hot pressing. According to different processes, people should choose different types of oil presses. Modern commercial peanut oil press machine has the functions of cold pressing and hot pressing. When selecting the hot pressing process, just turn on the heating switch on the screw oil extraction machine. Generally, the longer the pressing time, the more oil it can produce. However, the pressing time should not be too long. Therefore, under the premise of satisfying the oil output efficiency, the pressing time should be shortened as much as possible. As shown above, the TZ-80A has an output of 125-150kg/h. The output and size are based on the screw length. The various output of peanut oil press machines can meet the needs of small and medium oil production units.

Groundnut oil filling machine

Filling type: Piston Quantitative Filling

Filling capacity (2-head): 240KG-960KG

Filling volume: 500-3000ml

Filling accuracy: Error≤±1%

A peanut oil filling machine is an automatic machine for filling groundnut oil into bottles and other containers. The 2-head oil filling machine can fill two containers at the same time. For a 4-head oil filler machine, the filling efficiency is twice as productive as the two-head. There are many models of groundnut oil filling machines with different heads for options. The filling quantity can be set and the filling is highly accurate.

Features of peanut oil processing plant

- The groundnut oil production line has a wide range of options. Therefore, it can meet the production needs of different large, medium, and small peanut oil production institutions. Customers can choose the production line with the right output according to their own production output. Besides, you can also choose several machines instead of the entire peanut oil production line.

- Wide application. Apart from peanuts, peanut oil extraction machine can press rapeseed, sunflower seed, and other raw materials.

- High oil production efficiency and oil yield. The oil press adopts multi-stage propulsion squeezing. With an automatic temperature control function, you can set different temperatures for different oil materials. With the smart oil press, the groundnut oil production line’s oil output rate is greatly improved.

- The main components are made of high-quality steel, through advanced heat treatment technology such as carburizing. The service life of the equipment is more than 10 years.

How to choose the right peanut oil production plant?

In order to meet the needs of different customers, we, as an oil press manufacturer, produce a variety of models and output machines. Therefore, many machines in the peanut oil production line usually have multiple models. How to choose a peanut oil processing line depends on your business scale and expected output.

Cautions about peanut oil production

The squeezed peanut oil quality is not only related to the pressing process, it is also closely related to the quality of the peanut. Therefore, when using the oil expeller to press oil in the peanut oil production line, you need to pay attention to the following issues.

- Choose the peanuts of good quality with no mold. Moldy peanuts will have aflatoxin, which is very toxic.

- The oil extraction quality is also related to the operating proficiency of the operators. People who are not skilled in equipment operation may over-roast peanuts. The peanut oil squeezed with over-roasted peanuts will have a bitter taste, and the color of the peanut oil is not bright.

- Select good oil press and oil filtering equipment. Good oil pressing equipment has a long service life, and the oil filter removes impurities such as phospholipids in the oil.

- Pay attention to the storage of peanut oil after squeezing. It should be stored in a low temperature, dry, well-ventilated place.

If interested in our groundnut oil processing plant, please contact us directly. We will send you the quotation, videos, and machine details required.